Home » Linear Amplifier

Category Archives: Linear Amplifier

1kW Linear Amplifier Part 3: Build Up and Testing

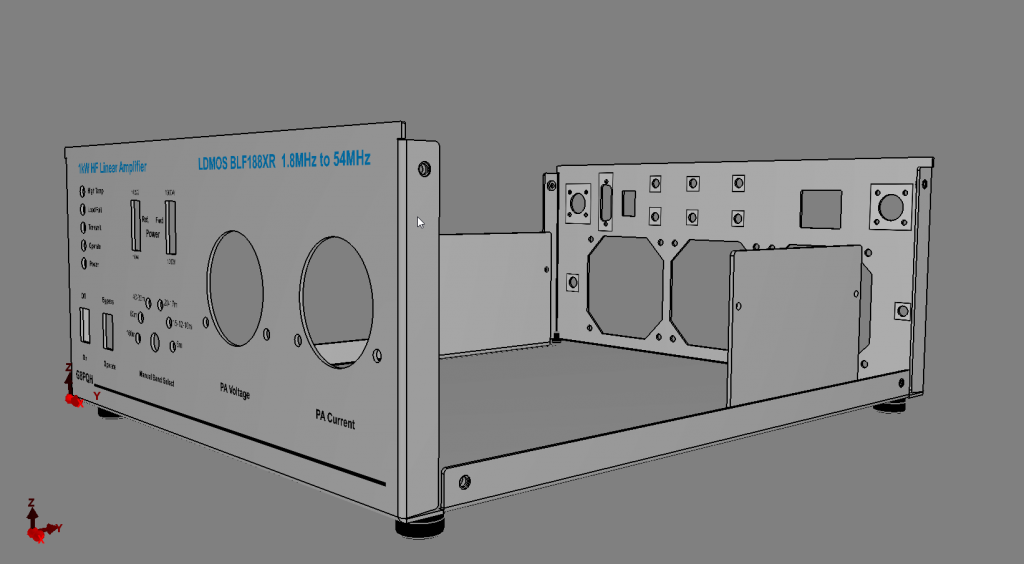

The general mechanical layout of the amplifier follows the W6PQL layout fairly closely.

The main difference is that the recommended heatsink he suggests is a bit expensive when you factor in shipping charges to the UK plus VAT & Customs etc. So I sourced a relatively inexpensive heatsink from the supplier TME in Poland which I think will have similar performance but is slightly longer, so makes the cabinet wider. This makes the whole box for the amplifier wider. For this reason I have the two meters for PA voltage and current side by side rather than one on top of each other as W6PQL does.

Mechanical Details

My metal working facilities are very limited, and my skill at it even more so. So rather than have separate panels bolted together I had a sheet metal box fabricated by an online vendor. A bit of a vanity project, as it looks nice and saves a lot of metal bashing, but is a cost. Another alternative could have been to mount the LPF alongside the heatsink and use a 19″ cabinet. That would be wider, but a lot shallower.`

Three fans are mounted on the rear panel along with RF connectors, power, PTT . SMA RF connectors are used to bring out connections to a 13dB 100W attenuator that can be placed in circuit when 100W transceivers are used to drive the amplifier, or bypassed when 5W radios are used to drive the amplifier. The heatsink is mounted at the rear lengthwise with the amplifier pallet and its copper heat spreader bolted to that.

The low pass filter assembly is mounted in front of the heatsink together with directional couplers for forward & reflected power display (after the filter) and amplifier load fail or wrong band lockout (before the filter). The front panel has metering, status LEDs, a band change switch with indicator LEDs and bar graphs for forward and reflected power.

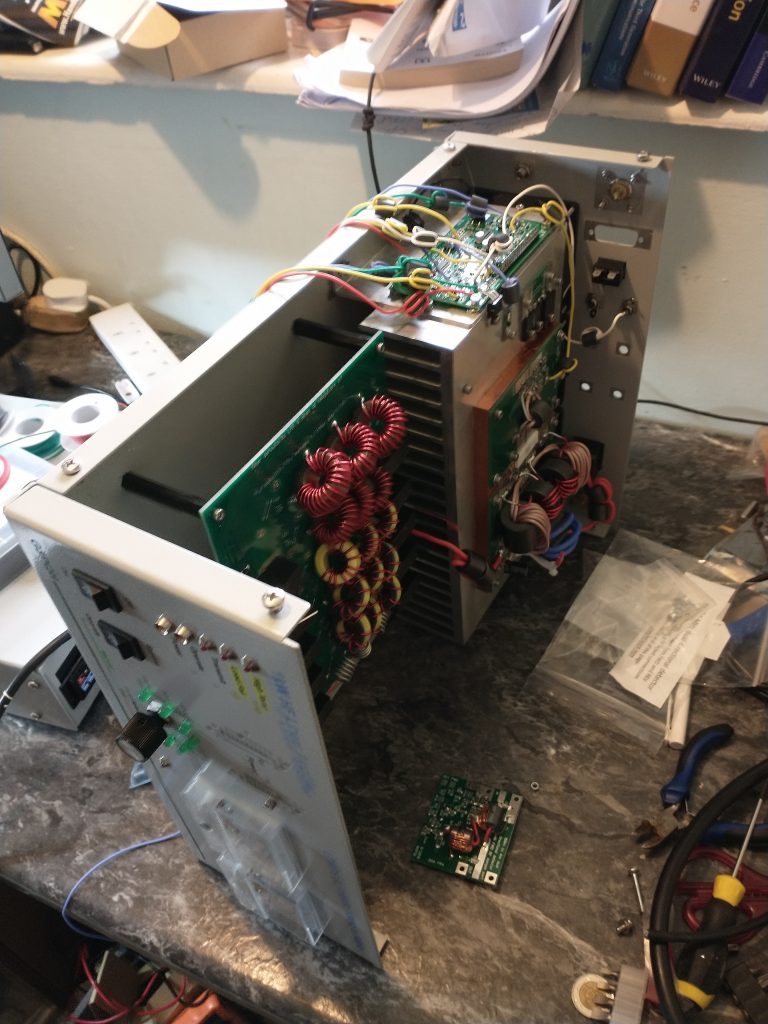

The photo above shows the amplifier under construction before most of the wiring. On the side of the heatsink the W6PQL control board can be seen with some of the control wiring.

Testing

This is a view of the finished amplifier with the covers off when testing into a dummy load.

The Tx/Rx relays can be seen mounted on the right hand side of the heatsink along with the low pass filter board in front of the heatsink. The smaller board mounted on the base is one of the two directional couplers used to sense forward and reflected power.

Initially the unit was powered up with a current limited bench supply that could go up to 30V at 3A. I first checked the control board circuitry was running and 13.8V was being generated for this and the relays etc from the 50V supply. The three fans mounted on the rear panel are powered from the 50V switched by the control board.

Putting the unit into transmit with no drive on the lab supply did not release any smoke. This was then swapped out for the 50V 40A supply for further tyesting.

Ebay was the source of a hefty dummy load rated at 1000W for 3 minutes and this was used for testing and to give a rough calibration to the two led displays on the front. The amplifier was able to produce around 1000W key down into the dummy load with varying levels of drive from the Sun SDR2 DX. With the 13dB attenuator on the amp input the drive level never went over 5W (100W into the attenuator).

The directional coupler is 10 times more sensitive for reflected power so the nominal LED scale is 0-100W for reflected and 0-1000W for forward. By my calculation then when both displays give similar readings the VSWR is 2:1 (approx 10dB return loss).

In normal operation the amplifier will be run to keep the output down to 400W or less. So I adjusted the LED meter sensitivity so the top display point was roughly around 600W measured on the CN801 cross needle power meter.

Next Steps

Driving the amplifier with another hf rig, say my K2, may free up the SDR wideband 0-80MHz receiver to be used to look for harmonic levels in the output and possibly intermodulation with a two-tone test. A spectrum analyzer would be better, but I dont have one!

A few cosmetic changes are needed, you will see I have mounted the to switches upside down (oops) and there are some cosmetic bits still to be fitted near the LED bar graphs.

1kW LDMOS Linear Amplifier – Part 2 Low Pass Filter

Based on designs by James, W6PQL

And in particular his HF LDMOS amplifier design described here:

https://www.w6pql.com/1_kw_sspa_for_1_8-54_mhz.htm

A key part of the amplifier is the switchable low pass filter design. This is designed to suppress the odd-order harmonics in the amplifier output which would be unacceptably high without it.

Construction

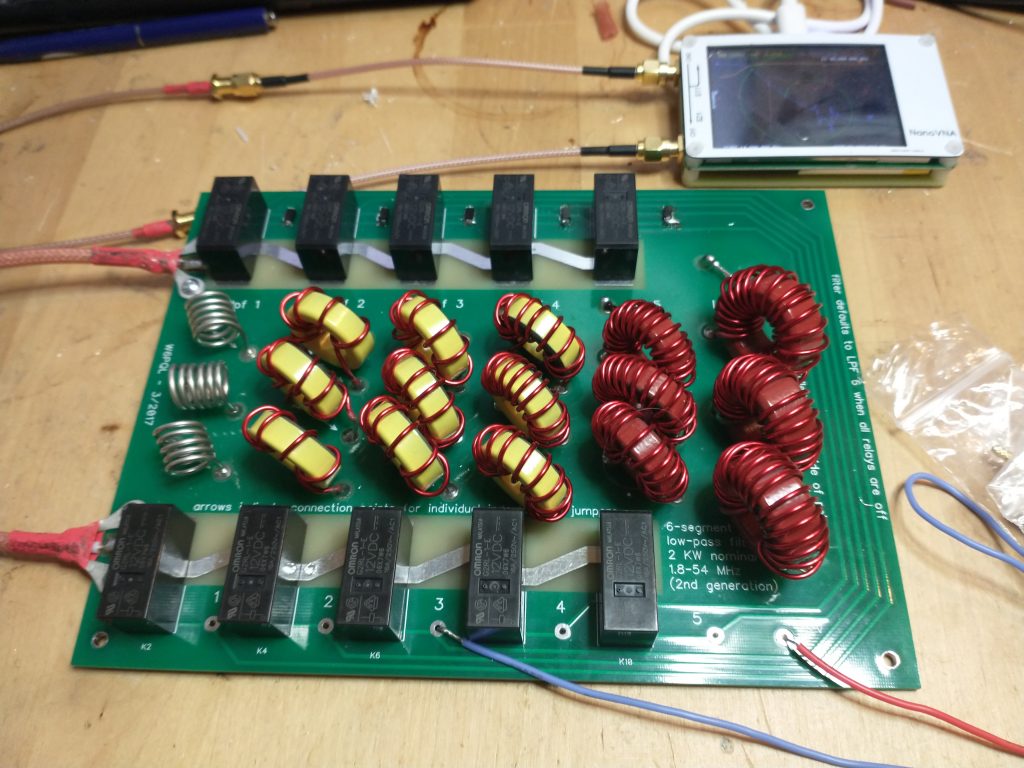

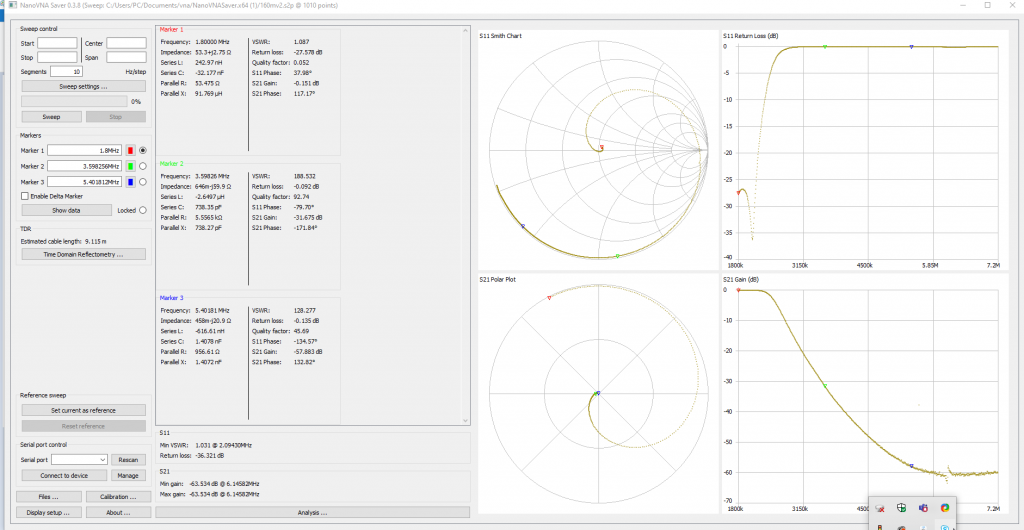

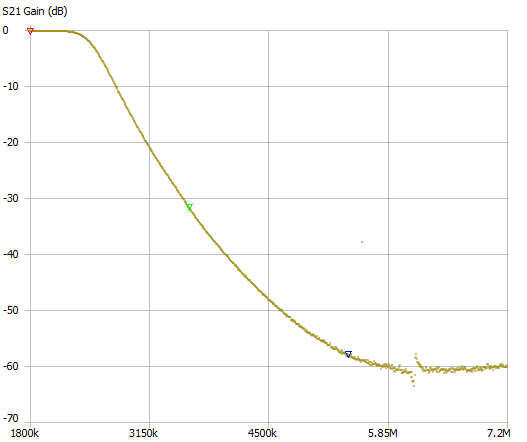

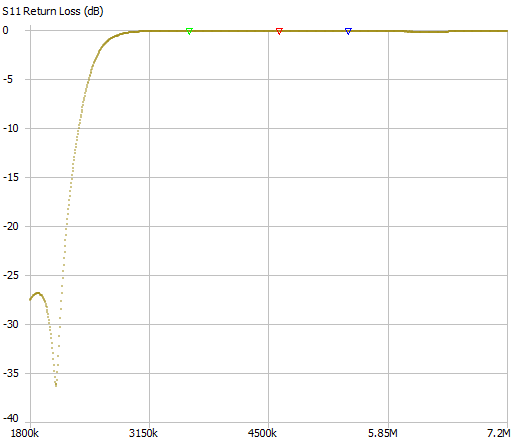

I built up the filter assembly from the the pcb and components supplied by W6PQL I tested it using the well known nanoVNA and the results are set out here.

A full description of James’s design can be found here: https://www.w6pql.com/a_1.5kw_lpf_for_160-6m.htm

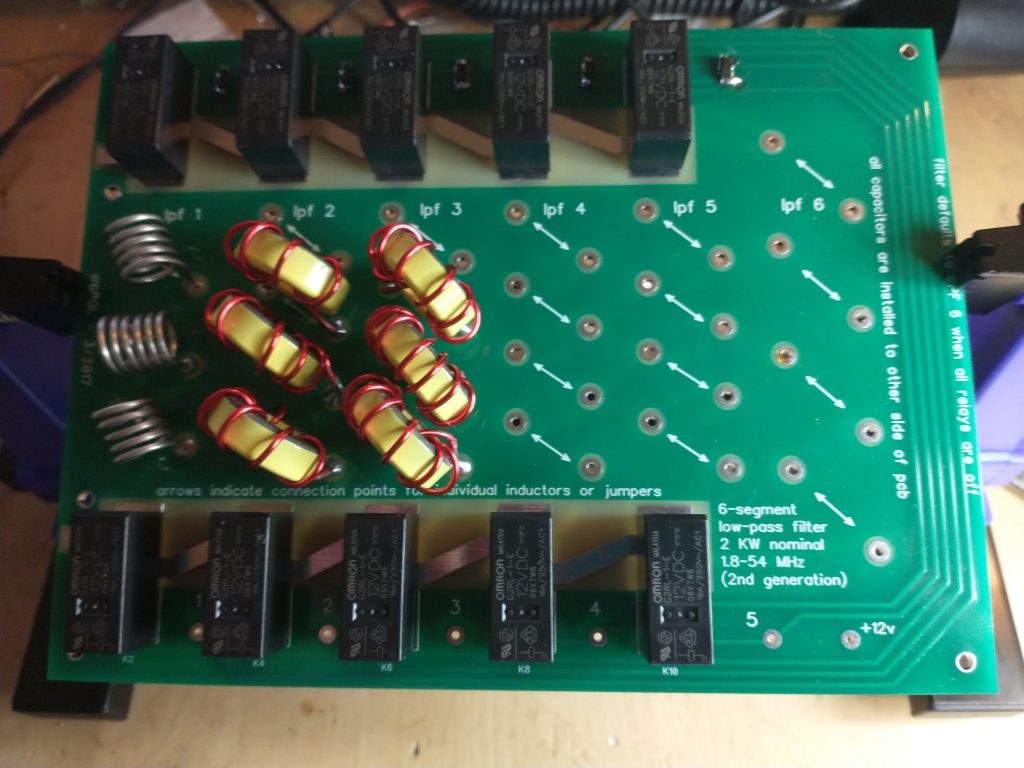

The board supports 6 different filters. With no relays energised the sixth filter for the 150m band (1.8-2MHz) is in circuit. Each of the five pairs of relays switch an alternative filter bank when energised by grounding the control inputs. The following filters are equipped:

- 160m band (default) <2MHz

- 80m band (#5) <4MHz

- 40m and 30m <10.2 MHz

- 20m and 17m bands <18.2MHz

- 15m, 12m and 10m bands < 30MHz

- 6m band <54MHz

Each of the low pass filter filter sections are 7-pole Chebyshev types which should give sufficient harmonic rejection.

The top side of the board has the relays and the toroidal coils, all except the 6m band use ferrites of different types. The bottom side has a great number of surface mount capacitors, which are easy to mount with some tweezers and patience, soldering one side at a time. (I managed to wick some solder between two adjacent capacitors to produce a hard to spot short in the 160m section which uses a lot of capacitors in parallel) But this was more or less the first time I had done much with SMD and easy to fix once spotted.

Testing

To test the assembly I made use of an inexpensive nanoVNA unit, bought from eBay. The VNA is the white box in the top right connected to a PC via a USB cable. The two SMA connectors on the VNA are cabled to the the input and output of the the filter unit. The red wire at the bottom right is feeding 12V from a bench PSU to the board. with no ground applied to the control inputs the 160m filter is in circuit. By grounding each of the five control inputs in turn with the blue wire each of the filters in turn is placed in circuit and the performance measured by the nanoVNA.

James, W6PQL has a collection of S21 gain/loss plots and S11 return loss plots on his web site. Being an ex HP engineer, I suspect he has access to a conventional high performance network analyser for his testing. However, I figured the nanoVNA would at least confirm the correct operation of the unit I assembled and highlight any errors in construction. In practice my results were very close to the example plots on the W6PQL website.

I have found it is much easier to use Ruhne Broberg’s open source software nanoVNASaver on the connected PC. Life is too short to spend too much time faffing about with the fiddly buttons and soft keys on the nanoVNA unit itself.

https://github.com/mihtjel/nanovna-saver/releases

Results – 160m band

Second harmonic suppression at 3.6MHz was around -32dB and third harmonic suppression at 5.4MHz was -58dB. The in-band return loss was always better than 25dB. The filtered harmonic content will be reflected directly back to the source as the return loss at these frequencies is zero.

Results – 80m band

Second harmonic suppression at 7MHz was around -30dB and third harmonic suppression at 10.5MHz was -53dB.

Results – 40m and 30m bands

Second harmonic suppression of the 7MHz (40m band) signal at 14MHz was around -20dB and third harmonic suppression at 21MHz was -48dB.

Results – 20m and 17m bands

Second harmonic suppression of the 14MHz (20m band) signal at 28MHz was around -27dB and third harmonic suppression at 42MHz was -49dB.

Results – 15m, 12m and 10m bands

Second harmonic suppression of the 21MHz (15m band) signal at 42MHz was around -17dB and third harmonic suppression at 63MHz was -45dB.

Results – 6m band

Second harmonic suppression of the 50MHz (6m band) signal at 100MHz was around -29dB and third harmonic suppression at 150MHz was -60dB.

Performance Implications

At 1000w key down the even order harmonics in the push-pull LDMOS design are reasonable but the odd-order harmonics are truly monstrous. W6PQL reports the third order harmonic as only 10dB down on the fundamental.

The minimum suppression of third order products in these filters is around 45 dB for the compromise filter covering three bands, 15m, 17m, and 10m. So at full power we might see a third order product at aroound-55dB below the carrier (-55dBc).

This is not too bad. In the USA amateurs must achieve -43dBc in part 97 of the FCC regulations. In the UK/EU its -50dBc for commercially built equipment intended for HF Amateur Radio use (-60dBc for other services). For UK amateurs building their own equipment the licence conditions are very “British” in their avoidance of prescription saying merely “the emitted frequency of the apparatus comprised in the Radio Equipment is as stable and as free from Unwanted Emissions as the state of technical development for amateur radio apparatus reasonably permits.”

I think hitting -50dBc in looks to be more than “reasonable” to me and should be possible.

Another important point is that UK amateurs are only allowed to run at 400W (26dBW) in most bands which is 4dB less than what the amplifier to be filtered is capable of. The designer doesn’t give any harmonic output figures when the amplifier is not driven so hard. However I would expect the 3rd harmonic to fall three times as fast as the fundamental, so be reduced by a further 12dB when run at the UK limit. This would indicate a worst case 3rd harmonic output at least -67dBc under these more benign conditions.

Running at 400W should also improve the in-band intermodulation performance of the amplifier.

1kW LDMOS Linear Amplifier – Part 1 (PSU)

Based on designs by W6PQL

First step in building such an amplifier as described here:

https://www.w6pql.com/1_kw_sspa_for_1_8-54_mhz.htm

is rigging up a power supply capable of delivering 50Volt at more than 35Amp.

There are a number of ways of doing this, telecoms power supply units (48V) can often be found on ebay, but like server power units can be very noisy. Its also possible to put together sets of 12 and 24 V switched mode PSUs with steering diodes etc to build a powerful combined unit. W6PQL describes such an approach on his web site.

I was lucky in that I managed to find a surplus Meanwell 48V 2400W power supply unit going cheap. Therefore my PSU is basically one of these units, encased in a slightly larger box with the addition of some switches and an ammeter to measure the current. Simple.

The connections are at the rear.

Inside its very simple.

In this image you can see the Anderson PowerPole connectors for the DC output on the rear and the cabling to them with ferrite beads aimed at reducing the RF on the wiring. Theres also a 75mV shunt on the negative output which is used to drive the ammeter on the front panel.

The pSU can be remotely turned on and off by shorting the remote input (two blue powerpole connectors) together from the attached LDMOS amplifier, or by setting the front panel switch to local.